Ndoko

Umi

Dan 1.4404 / AISI 316L, DR 1.4539 / AISI 904L

Mone, onye dustral, duel steel, hastelselloy alloys

Ihe ndị ọzọ dị na arịrịọ.

Funiness Fness: 1 -200 microns

Nkowa

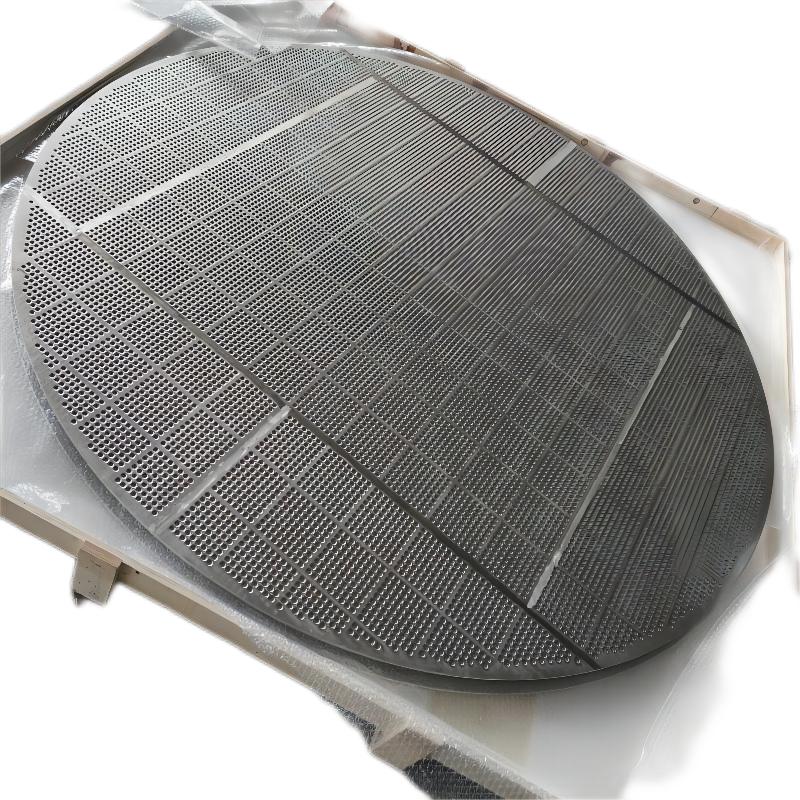

| Nkọwapụta - Punching efere efere waya waya | ||||

| Nkowa | Mekọta goofu | Ndoko | Okpurukpu | Nduodosu |

| μm | mm | % | ||

| Ssm-p-1.5t | 2-100 | + 60 + 30 + φ4x5px1.0t | 1.5 | 57 |

| Ssm-p-2.0t | 2-100 | 30 + Mepee φ5x7px1.5t | 2 | 50 |

| Ssm-p-2.5t | 20-100 | 6 60 + na-enyocha ya 30 + φ4x5px1.5t | 2.5 | 35 |

| Ssm-p-3.0t | 2-200 | 6 60 + φ6x8px2.0t | 3 | 35 |

| Ssm-p-4.0t | 2-200 | 30 + φ8x10px2.5T | 4 | 50 |

| Ssm-p-5.0t | 2-200 | 30 + 12 + φ8x10PX33.0t | 5 | 55 |

| Ssm-p-6.0t | 2-250 | 30 + 12 + φ8X10PX4.0t | 6 | 50 |

| Ssm-p-7.0t | 2-250 | 30 + 12 + φ8x10PX5.0t | 7 | 50 |

| Ssm-p-8.0t | 2-250 | 30 + 12 + φ8X10PX6.0t | 8 | 50 |

| Enwere ike ịhazi ya na eriri na usoro nke waya ka enwere ike ịhazi ya dịka onye ọrụ si dị. | ||||

A na-eji ya eme ihe na nzacha na-akpụ akpụ akpụ akpụ akpụ nwere ike ịbụ ọkọlọtọ ise na pharching break.

Nke ahụ bụ 100 + nzacha + 100 + 12/64 + 64/12 + 4.0T (ma ọ bụ nke ndị ọzọ na-adọta efere)

Ọkpụkpụ nke Punching Plate A na-achọkarị na nrụgide gị.

Ngwaahịa a dị mma maka gburugburu mgbali elu ma ọ bụ nrụgide dị elu na-enye nkwado dị elu, na-edozi mmepụta na-aga n'ihu na ụlọ ọrụ na-aga n'ihu na nkwado ndabere na ntanetị, ihe na-emepụta ihe na-enye nkwado n'ịntanetị.

Ngwa

Nri & ihe ọverageụ, mmiri na-ewepu, ndị na-ere ọgwụ, kemịkal, polymer, wdg.

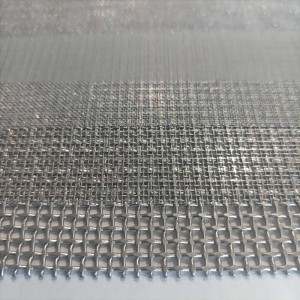

Mpempe akwụkwọ dị omimi na-egbu egbu bụ ụdị mkpokọta kegide na ndị na-esite na poraus efere na ntọala dị larịị jikọtara ọnụ. Enwere ike ịhọrọ efere ahụ dị iche iche dị iche iche dị na mkpa, na ụgbụ na-adọrọ adọrọ nwere ike ịbụ otu ma ọ bụ karịa n'ígwé ma ọ bụ karịa. N'ihi nkwanye ugwu dị ka nkwado, usoro ndị mejupụtara ya nwere ike na ike na-eme ihe ike. Ighapu nke abuo abughi nke nwere ezigbo ikuku nke ulo ntuli aka nke akpukpo ahihia akpọrọ, kama ha nwere ike nke oma nke mmanu mmanu. Enwere ike ịhazi ya n'ime cylindrical, diski, mpempe akwụkwọ na mkpokọta, ihe ọ beụ, nri, Mitallingy, kemịkal ọgwụ, wdg.

Njirimara mmanụ dị nkọ

(1) ezigbo ego na ike igwe dị elu. N'ihi nkwanye ugwu na-akwado, ọ nwere ike kachasị elu na ike dị omimi n'etiti mesh;

(2) nkenke nzacha nke nzacha, ọnụ ọgụgụ nke nzà nzà agbaze bụ 1μ - 100μ, ọ nwere arụmọrụ na-agbanwe agbanwe;

(3) Dị mfe ịdị ọcha, a na-anabata elu elu elu, karịsịa ọfụma maka ịkwado ndabere;

(4) Ọ naghị emebi ngwa ngwa, ọdịdị nke mesh guzobere, nha ọdịiche ahụ bụ edo edo, ma ọ dịghị olulu ọ bụla.

(5) corrosion iguzogide, nguzogide elu di elu, nwere ike iguzo elu nke 480 ℃.

Mpekere efere e jikọrọ ọnụ

(1) ihe eji eme ihe maka ịgbasa oyi na gburugburu ebe obibi dị elu.

(2) maka ngwa nke otu gas gas na ụlọ ọrụ ntụ ntụ, efere ndị ahụ na-acha uhie uhie na ụlọ ọrụ nchara.

(3) ortiventive ihe maka akwa nke gas na-acha uhie uhie.

(4) A na-eji ya na mgbochi ọkụ ọkụ na-acha odo odo na-agbasa na na-eme ka usoro dị egwu.

(5) Filetration, ịsa na ihicha ihe na ụlọ ọrụ ọgwụ.

(6) Nkwado Nkwado Goy.

(7) A na-eji ya maka ngbanwe nke polyester, mmanụ, nri na ihe ọveụ, ụfụfụ, yana maka ọgwụgwọ mmiri na feltation.