Nhazi

Akụrụngwa

DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, Duples ígwè, Hastelloy alloys

Ngwa ndị ọzọ dị na arịrịọ.

Ịdị mma nzacha: 1-200 microns

Nkọwapụta

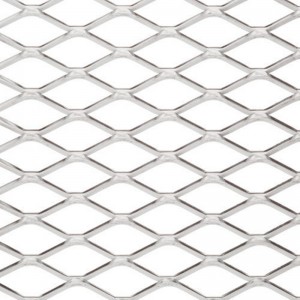

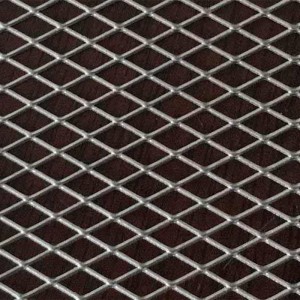

| Nkọwapụta - Punching efere sintered waya ntupu | ||||

| Nkọwa | iyo mma | Nhazi | Ọkpụrụkpụ | Porosity |

| μm | mm | % | ||

| SSM-P-1.5T | 2-100 | 60+ filter oyi akwa+60+30+Φ4x5px1.0T | 1.5 | 57 |

| SSM-P-2.0T | 2-100 | 30+ filter oyi akwa+30+Φ5x7px1.5T | 2 | 50 |

| SSM-P-2.5T | 20-100 | 60+ filter oyi akwa+60+30+Φ4x5px1.5T | 2.5 | 35 |

| SSM-P-3.0T | 2-200 | 60+ filter oyi akwa+60+20+Φ6x8px2.0T | 3 | 35 |

| SSM-P-4.0T | 2-200 | 30+ filter oyi akwa+30+20+Φ8x10px2.5T | 4 | 50 |

| SSM-P-5.0T | 2-200 | 30+ filter oyi akwa+30+20+16+10+Φ8x10px3.0T | 5 | 55 |

| SSM-P-6.0T | 2-250 | 30+ filter oyi akwa+30+20+16+10+Φ8x10px4.0T | 6 | 50 |

| SSM-P-7.0T | 2-250 | 30+ filter oyi akwa+30+20+16+10+Φ8x10px5.0T | 7 | 50 |

| SSM-P-8.0T | 2-250 | 30+ filter oyi akwa+30+20+16+10+Φ8x10px6.0T | 8 | 50 |

| Enwere ike ịhazi ọkpụrụkpụ nke efere ọkpọ ọkpọ na nhazi nke eriri waya dịka ihe onye ọrụ chọrọ. | ||||

N'ikwu ya, ọ bụrụ na-eji na Multifunctional nzacha ịsacha dryers, nzacha efere Ọdịdị nwere ike ịbụ ọkọlọtọ ise oyi akwa na punching efere sintered ọnụ.

Nke ahụ bụ 100+ filter oyi akwa+100+12/64+64/12+4.0T(ma ọ bụ Nke ọzọ ọkpụrụkpụ ọkpọ ọkpọ)

Ọkpụrụkpụ nke efere ịkụ ọkpọ na-adaberekwa n'ọchịchọ nrụgide gị

Ngwaahịa a dị mma maka gburugburu nrụgide dị elu ma ọ bụ ọchịchọ ịsa azụ dị elu, na-edozi nke ọma na-emepụta ihe na-aga n'ihu nke ụlọ ọrụ ọgwụ na chemical na online backwashing, akpali mmasị mmepụta chọrọ.

Ngwa

Nri & ihe ọṅụṅụ, ọgwụgwọ mmiri, iwepụ uzuzu, ụlọ ahịa ọgwụ, chemical, polymer, wdg.

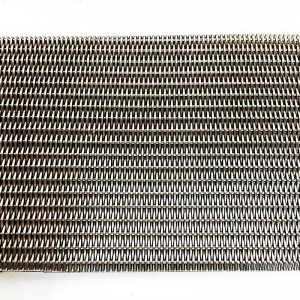

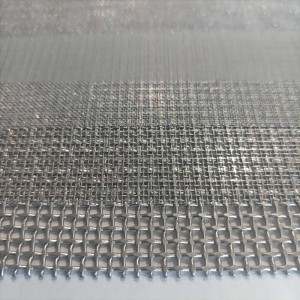

Ọkọlọtọ ntupu ihe nzacha nwere oyi akwa ise bụ nke a na-atụgharịkarị site na ihe nzacha ihe nzacha nwere oyi akwa ise.Ọkọlọtọ waya sintered nke nwere oyi akwa ise bụ akwa nchara ise nke igwe anaghị agba nchara nchara n'elu na oghere sintered.Ihe nzacha a na-eme nke ọkọlọtọ ntupu nke nwere akwa ise nwere njiri mara nke nguzogide corrosion siri ike, ike dị elu, ike dị elu, nhicha dị mfe na ihicha azụ, izi ezi nke nzacha edo, ịdị ọcha na ihe nzacha dị ọcha, yana ntupu waya anaghị agbapụta.

Meshes nke ọ bụla oyi akwa nke sintered mesh filter element na-ejikọta ọnụ iji mepụta otu na ezigbo nzacha nhazi, nke na-eme ka ihe ahụ nwee uru na-enweghị ike iji ya tụnyere nchara ígwè nkịtị, dị ka ike dị elu, ezigbo isi ike, na ntupu.udi kwụsie ike wdg N'ihi ezi uche kenha na imewe nke pore size, permeability na ike e ji mara ihe, o nwere magburu onwe filtration ziri ezi, filtration eguzogide, n'ibu ike, eyi iguzogide, okpomọkụ na-eguzogide na processability, na keukwu arụmọrụ ka mma. .Dị elu karịa ụdị ihe nzacha ndị ọzọ.

1. Njirimara ngwaahịa:

1) Ntupu nke nwere akwa ise nke nwere akwa mkpuchi mkpuchi, ihe nzacha ihe nzacha, akwa mgbasa ozi na ọkpụkpụ ọkpụkpụ abụọ;

2) Ike dị elu: mgbe ọ gbasasịrị eriri waya nke ise oyi akwa, ọ nwere ike ọrụ dị elu na ike mkpakọ;

3) High nkenke: Ọ nwere ike itinye edo n'elu filtration arụmọrụ maka filtration urughuru size nke 1 ka 200um;

4) Nguzogide okpomọkụ: Enwere ike iji ya mee ihe maka nzacha na-aga n'ihu site na -200 degrees ruo ogo 650;

5) Cleanability: N'ihi usoro nzacha elu nke nwere mmetụta nhicha dị mma na-adịghị mma, nhicha dị mfe.

6) Ọ nwere ezigbo permeability na ike dị elu, ọ dịghị mkpa ịgbakwunye usoro nkwado, ọ dịghị ihe na-adaba na-emekarị, nkwụsị nke corrosion siri ike, dị mfe ihicha na ọ dịghị mfe imebi.

2. Ebumnuche bụ isi:

1) A na-eji ya dị ka ihe na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na gburugburu ebe okpomọkụ dị elu;

2) Eji ya maka nkesa gas, orifice efere ihe maka akwa mmiri mmiri;

3) Maka ihe nzacha dị elu, ihe nzacha dị elu nke nwere ike ịdabere na ya;

4) N'ihi na elu mgbali backwash mmanụ filter

5) Ejiri ya maka nzacha nke polyester, ngwaahịa mmanụ, ọgwụ, nri na ihe ọṅụṅụ, ngwaahịa kemịkalụ na kemịkalụ, yana maka ọgwụgwọ mmiri na gas filtration.

Rịba ama: Enwere ike ịmepụta akụkụ dịka ihe ndị ahịa chọrọ.Enwere ike ịhazi ya ka ọ bụrụ tubular, diski, kandụl na ihe nzacha ndị ọzọ.